Linoleum — the most popular material for covering floors. It is used both in institutions and at home. As a rule, linoleum is sold in rolls, so if it is always enough in length, then in width — definitely not. Then you have to resort to its welding — cold or hot. Когда надо куплю мазут топочный недорого по приведенной ссылке.

At home, in small offices, where the cross -country cross -country is quite low, they use soft linoleum, so to speak, household. Such linoleum has many colors. Cold welding is used for domestic linoleum. This is a special glue that fill the boundaries of two linoleum strips, reliably gluing them. This method provides both the reliability of gluing and almost the invisibility of the seam itself.

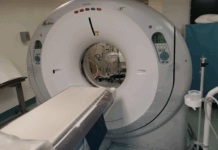

In large institutions, with great cross -country ability (for example, medical institutions, production, large shopping centers) use commercial linoleum. In its structure, such linoleum is more firm and denser than the usual one has increased wear resistance. To glue the joints of such linoleum, hot welding is used. Its technology lies in the fact that in the joint between the linoleum canvases the cord lays, harmonizing with the color of linoleum in color, and at high temperatures it melts, reliably gluing the seam. When working with hot welding, you need a special welding device, which should work with a qualified specialist.